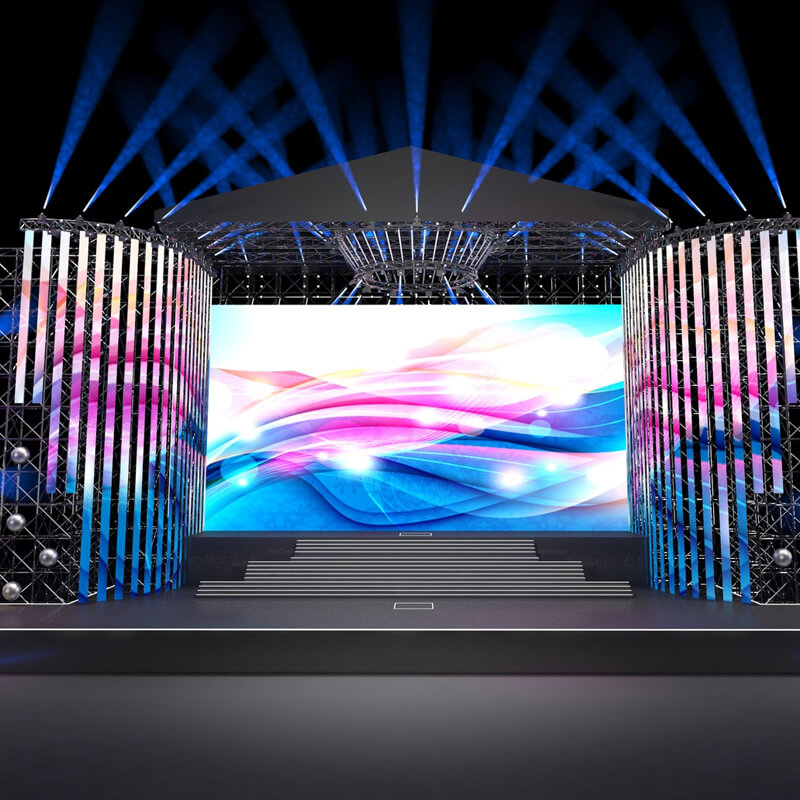

Why Weatherproofing is Essential

Outdoor environments are unpredictable. Rain, high humidity, UV rays, dust storms, and even snow can damage electronic components. Without proper weatherproofing, LED panels may suffer from corrosion, electrical failures, or reduced brightness. Weatherproofing ensures that these displays operate efficiently throughout the year, regardless of weather conditions

Key Materials Used for Weatherproofing

Manufacturers use specialized materials to safeguard LED video walls from environmental stress. Some of the most common materials include:

1. Aluminum and Stainless Steel Frames

Frames and enclosures made from rust-resistant aluminum or stainless steel provide structural strength while resisting corrosion. These metals are lightweight yet durable, ideal for outdoor installations.

2. Protective Coatings

PCB boards and internal components are coated with conformal layers that resist moisture and dust. These coatings help prevent short circuits and component degradation.

3. High-Quality Seals and Gaskets

Rubber or silicone gaskets are used around panel edges, connectors, and joints to block water and dust ingress. This prevents internal damage during heavy rain or dust storms.

Conclusion

When investing in outdoor LED video walls, weatherproofing should be a top priority. Using high-quality materials, protective coatings, and adhering to international standards like IP and IK ratings ensures durability and excellent performance. Whether for advertising, public information, or entertainment, weatherproof LED screens deliver visual impact with the resilience needed for the outdoors.