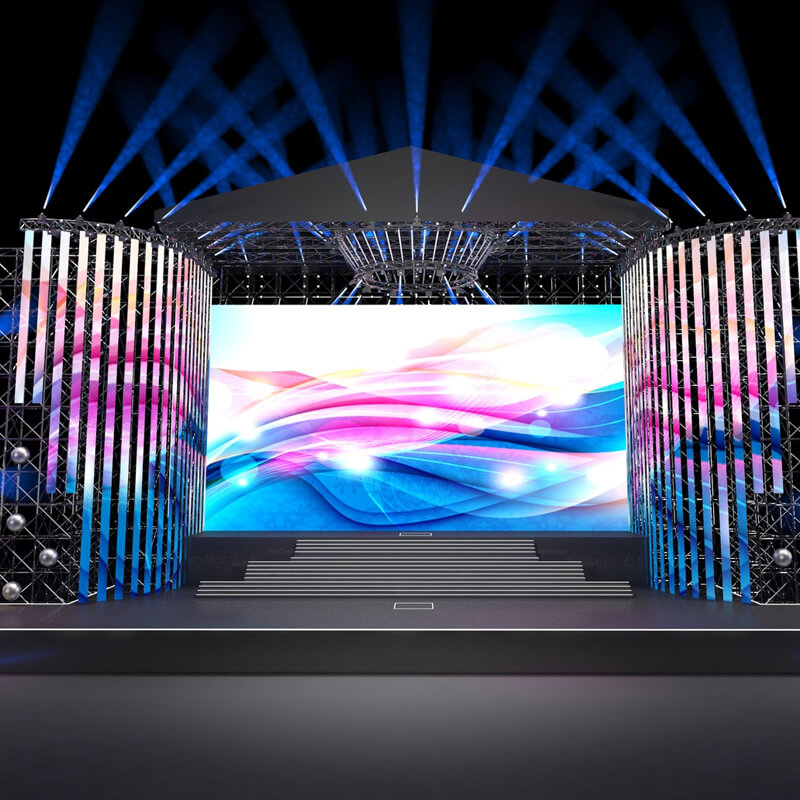

INTRODUCTION

LED displays have become a common sight in everything from advertising billboards to stage backdrops, retail stores, sports stadiums, and corporate lobbies. But have you ever wondered what lies beneath the vibrant visuals and high-resolution content? In this blog, we’ll take you behind the screen to explore the core components and technology that make LED displays work seamlessly.

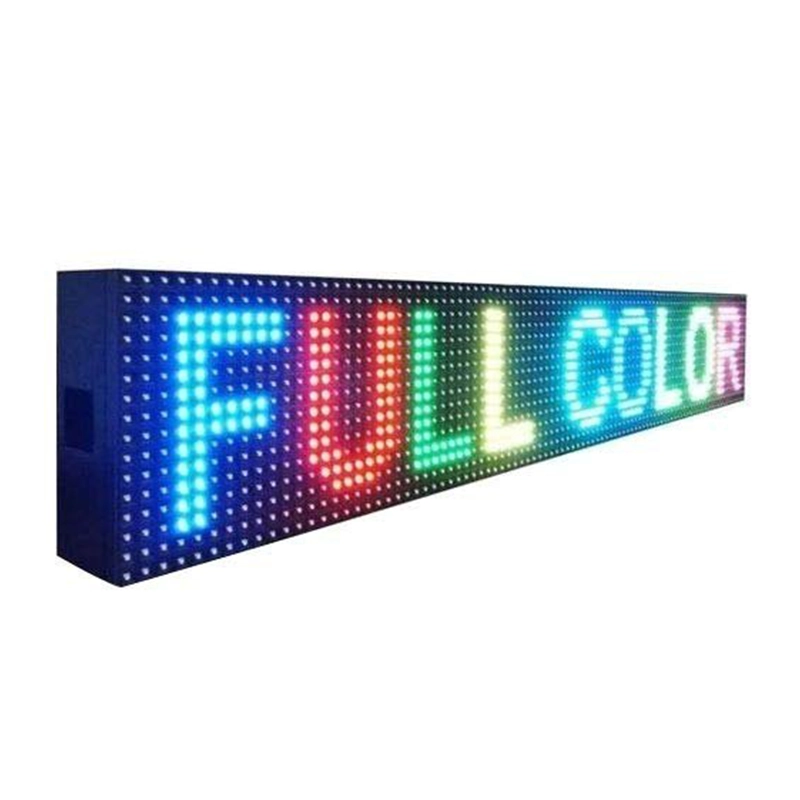

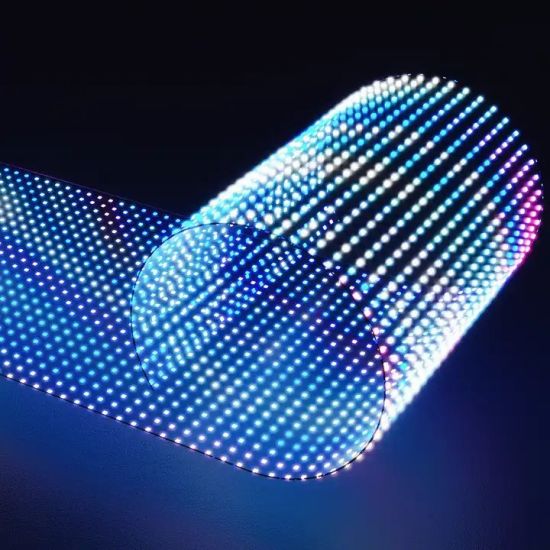

LED Modules: The Building Blocks

At the heart of any LED screen is the LED module. This module consists of clusters of tiny light-emitting diodes (LEDs) arranged in a matrix pattern. Each LED emits red, green, or blue light (RGB), and by adjusting their brightness, the screen can produce millions of color combinations. The quality, brightness, and resolution of the screen largely depend on the pixel pitch (distance between the LEDs) and the type of LEDs used—SMD (Surface Mounted Device) or DIP (Dual In-line Package).

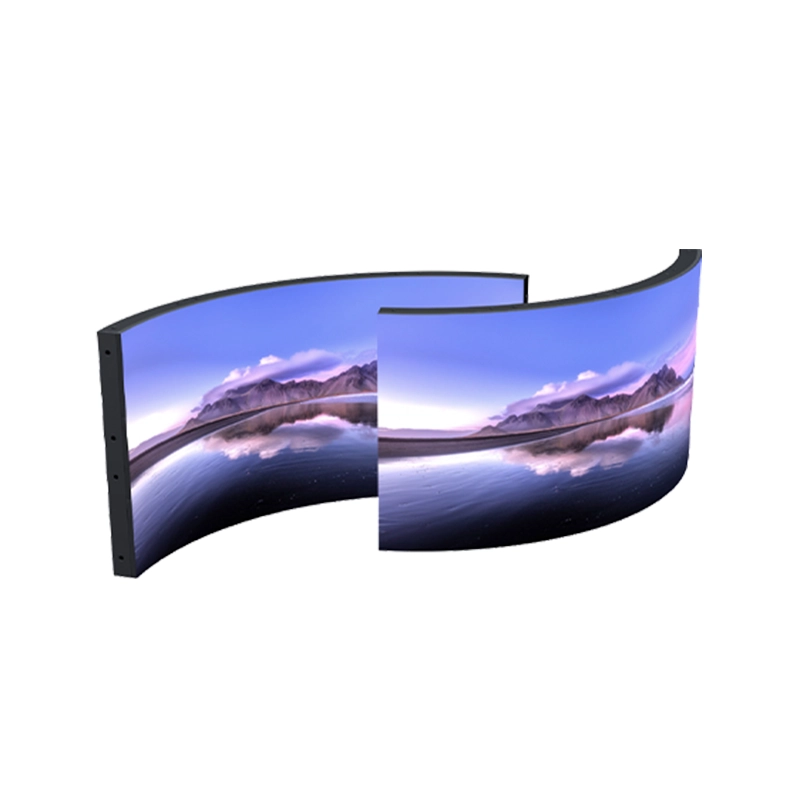

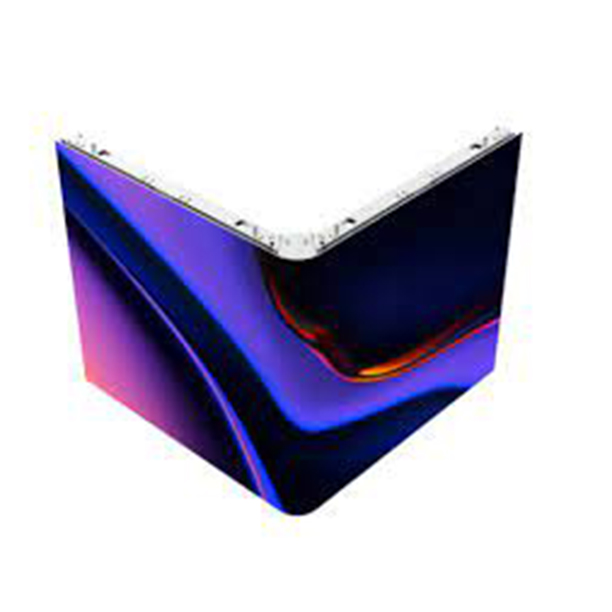

Cabinet: The Structural Frame

Multiple LED modules are mounted onto a cabinet, which acts as the structural housing. These cabinets are designed to be lightweight, yet sturdy, and often made from aluminum or die-cast materials. They come in standardized sizes and are designed to interlock seamlessly for easy assembly of large video walls. Proper ventilation is also integrated to manage heat dissipation.

Control System: The Brain Behind the Screen

The control system is like the brain of the LED display. It comprises two main parts: the sending card (or controller) and the receiving card. The sending card processes video input from external sources like laptops, media players, or processors. It then transmits the data to the receiving card located inside the screen, which distributes the signal to each module to display the image.

Power Supply Unit (PSU)

Each LED cabinet contains a power supply unit that converts the incoming AC power into low-voltage DC current suitable for the LED modules and control system. A stable and efficient PSU ensures that the screen operates without flickering or damage due to voltage fluctuations. High-quality power supplies also improve the screen’s longevity and energy efficiency.

Data and Power Cables

To keep everything connected, LED displays use a network of data and power cables. These cables ensure the transfer of control signals and power from one module to another. Proper cable management and shielding are crucial to prevent interference and ensure smooth performance, especially in large or outdoor installations.

Cooling System: Managing Heat

LED displays generate heat, especially in high-brightness outdoor units. To prevent overheating, cabinets are designed with cooling mechanisms—usually a combination of ventilation grills, fans, or heat sinks. Efficient thermal management is essential to maintain consistent brightness and avoid component failure.

Protective Coating & Enclosure

For outdoor displays, additional layers of protection such as waterproof coatings, anti-UV treatments, and weather-resistant enclosures are applied. These ensure durability against rain, dust, wind, and sunlight. IP ratings (Ingress Protection) are used to classify the level of protection each display offers.

Conclusion

When choosing an LED display, especially for outdoor applications, it’s crucial to look beyond size and resolution. High brightness and long-lasting quality are not just technical specifications—they are the foundation of performance, reliability, and brand success. At NovaView LED Screen (NVS) Pvt Ltd, we ensure our displays combine cutting-edge brightness with rugged durability, giving you value that truly shines over time.